1.1 Electronics Matters

Electronics are ubiquitous. We light our homes, communicate, navigate, socialize, inform, compute, and perform myriad other activities through the use of electronic devices and technologies. Chances are, you’re reading this text now on an electronic device such as a portable e-reader or a laptop. Your smart phone is probably nearby. You may be wearing a smart watch. A long-life, energy efficient LED lamp is probably lighting up the room you’re in. And a motion sensor hidden away in the corner might be informing the light controller that you are, in fact, in the room and in need of light. Perhaps you’ve checked, been tempted to check, or been summoned by an alert to check your phone since you started reading this paragraph. Your morning coffee may have been poured by a machine that turns on at a pre-determined time. Did you drive today? Your car has several thou….You get the picture: You’re surrounded by electronic devices and they enable you to do whatever it is that you do throughout your day. The design of these devices and the means by which electrical energy is used to power them, is the stuff of electrical engineering.

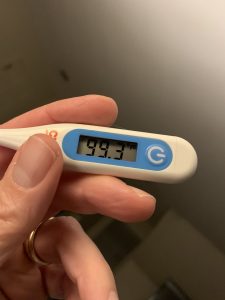

This ebook was first drafted during 2020, during the height of the coronavirus pandemic. Hospitals were struggling to adapt, almost overnight, to the inrush of infected and critically ill patients who developed the covid infection and need care. Body “vitals” such as temperature, blood pressure, and blood oxygen concentration, were being monitored by so many people, including people at home, that it was difficult, it took longer, and it cost more due to the demand surge, to buy basic health measuring instruments.

Many patients needed intensive care and some needed mechanical respirators to help them breath. Hospital rooms were converted into intensive care units (ICUs) and an agonizing, intensive global search for additional mechanical ventilators to install at ICU beds took place. The supply of ventilators, relative to the need, was so critical that, in some cases, ventilators were shared between two people, and “who gets saved” plans were implemented.

It goes without saying that all this health care was and continues to be dependent on instruments, displays, and information systems based on electronics and developed by teams comprised of electrical, biomedical, mechanical, industrial, and computer engineers, in addition to other professionals. While all this is going on in 2020, hospitals remained low on Personal Protective Equipment, or “PPE”: the gowns, masks, goggles. and gloves that nurses and doctors change into when entering the room of an infected patient, so as to minimize contamination. The demand so exceeded the supply that PPE was being reused and rationed in hospitals. The Baystate Medical Center, in Springfield, MA, is one such hospital that had to manage this situation.

Baystate Respirator Article Link

During normal times, medical staff are able to don fresh PPE whenever they enter an infected patient’s room to monitor that patient’s vitals or make individualized adjustments to the settings of their ventilators. Owing to the lack of PPE, the medical team at Baystate wanted to remove the control panels from the Servo-i ventilators in the patient rooms and deploy the panels out in the hallway. This would enable medical staff to monitor and adjust the ventilators without needing to don PPE and enter the room of an infected patient. The cable connecting the control panel and the ventilator itself was too short to enable this change.

The hospital also has an inventory of 45 EVP200 ventilators. These are portable ventilators used for increasing capacity during surge events; each ventilator operates on 2 D-size batteries that need to be replaced every 48 hours. The medical staff wanted to modify these ventilators to operate on AC “wall outlet” power, while keeping the batteries as a backup power supply, thereby eliminating the need to continually enter patient rooms to replenish batteries.

During March of 2020, representatives of the Baystate Medical Center asked the UMass electrical and computer engineering (ECE) Department for help with two problems: (1) increasing the cable length between the patient ventilation unit and the control panel on the Servo-i ventilators, so that the panel could be placed outside the patient room, in the hallway, to save PPE; (2) adapt the power supply of the EVP-200 ventilators to enable the entire inventory of these instruments to be plugged into the wall for “AC power” while keeping the batteries as a back-up against a power failure. A team of engineers from UMass ECE worked with the hospital to come up with engineering fixes for these problems and they helped arrange for the professional supply and production of materials needed to make the change across the inventory of ventilators. The details of this relatively-simple but critical and, indeed, life-saving fix are described later in this ebook.

Electronics for non-EE’s. As an engineer, you may well be called upon to participate in solving problems like the ones described here. The solution requires an understanding of patient care and it requires innovation — coming up with creative, useful ideas to deal with constraints related to testing, supply chain, and manufacturing. The solution also requires an understanding of electrical engineering fundamentals, including concepts of voltage, current, resistance, power, energy and other topics and an ability to apply that understanding to solving problems. Hopefully, your engineering skills will be put to use in less stressful times doing a wide variety of useful and interesting projects; many of them will likely involve some interface to EE topics just as the Baystate ventilator problem did. The goal of this book, and the course it supports, is to help you tackle such problems with knowledge and confidence.